Custom Steel Bicycle

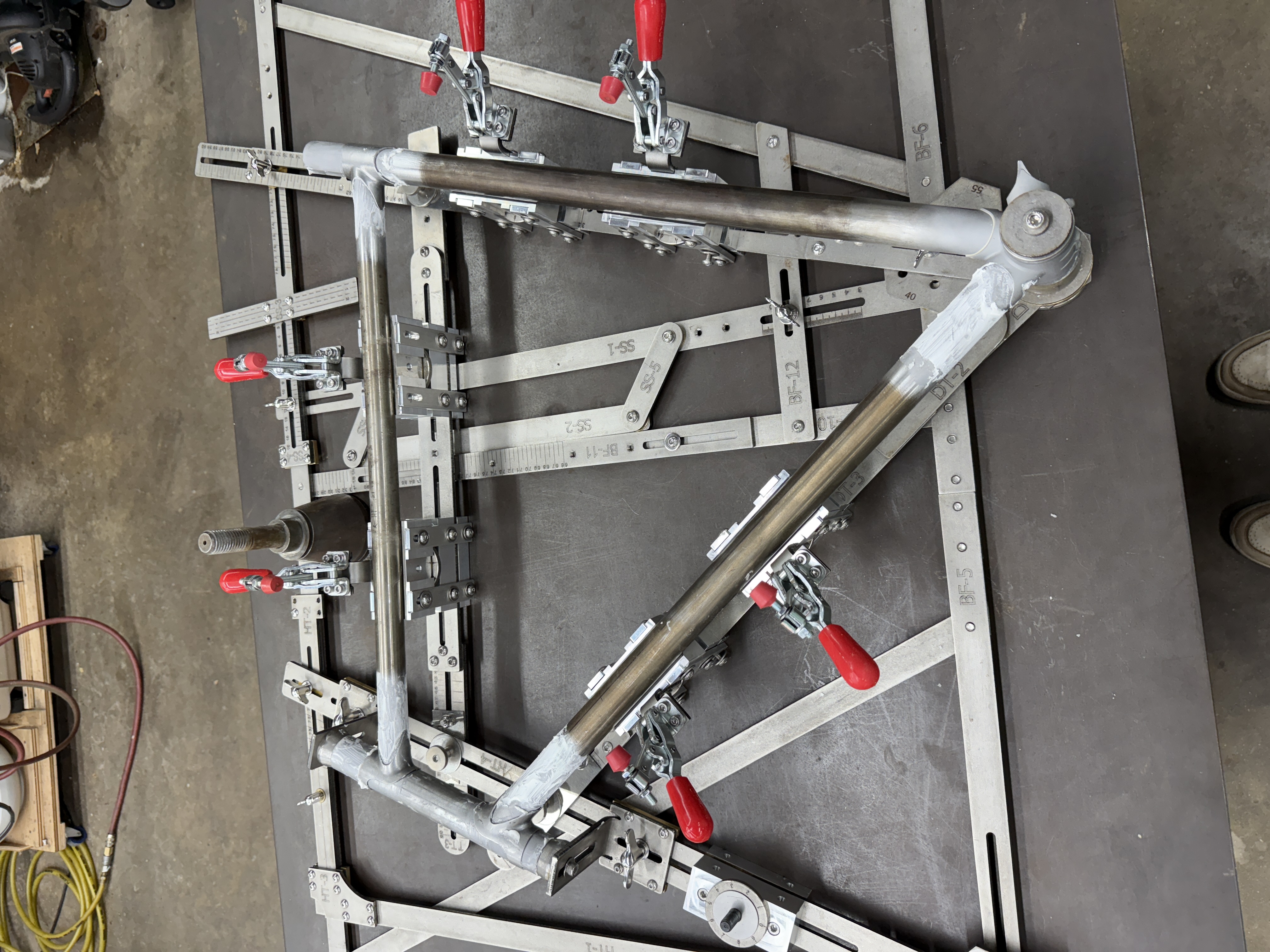

In Summer 2025, I spent a month studying under Doug Fattic, an internationally renowned frame builder. In my studies, I learned to design and build a custom steel lugged bicycle. The manufacturing processes I learned include brazing, coping, sawing, filing, and painting. I took great care learning proper hand filing and sawing techniques and tool selection. I used 10 files and 2 saws for everything from tube mitering to lug filing. I used silver braze to join tubes at their joints and brass braze for screw-in bosses. The first half of the class was spent learning bicycle fitting, design, and component selection. I ultimately left the class with a wealth of knowledge and a custom bike built for touring, which I plan to ride from Seattle to Key West in Summer 2026.